armstrong commercial flooring installation instructions

Draw a pencil line on the subfloor along the length of the trimmed factory edge. You are currently on the United States English Armstrong Flooring site.

Deco Vintage Floor And Wall Old Blue Sea Aged 6 In X 36 In Painted Style Luxury Vinyl Plank 30 Sq Ft Case D Luxury Vinyl Plank Vinyl Plank Luxury Vinyl

If you have installation questions about a product not listed please contact our TechLine Experts at 877-276-7876.

. Excelon vinyl tiles will bring out the hidden artist in you. Additional installation tips can be found in the Installation Channel of our video library. Post date September 25 2019.

After installation temperature should not fall below 65 F 18 C for the first 48 hours and not below 55 F 13 C after that. Prepare the seam edge on the opposite side of the sheet by trimming the factory seam edge using an edge trimmer. Armstrong Flooring with S-295 S-299.

Apply the Adhesive over the area being careful not to cover the chalk lines. Do not overlap the underlayment at any point in the installation. Newly installed commercial flooring should not be exposed to routine rolling load traffic carts lifters etc for at least 72 hours after installation to allow setting and drying of adhesives.

Post author By admin. If repairs are needed make those before starting the installation. Thanks for visiting us.

Install finish molding vertically at one end of the installation. Were here to help. You may prefer to install one quarter of the room at a time by starting in the center of the room Refer to Layout and Fitting section for layout instructions.

Maintain a minimum temperature of 55 F 13 C thereafter. If room is heated by radiant coils in the subfloor the temperature of the floor surface should not exceed 85 F 29 C. Light Commercial Commercial Installations- Must be installed using a 332 24 mm bead of glue on the END groove ONLY.

Grain direction runs parallel with the length of the panels. Installation should be started with the Male side closest to the wall Fig 2. Line off entire area to be installed.

In areas of direct sunlight heavy rolling loads or high traffic the S-1841 should be glued to the subfloor. 1 800 233 3823. For product availability and information for your current location you.

Line off entire area to be installed. Keep room at minimum of 65 F 18 C during that time and during installation. Instructions on removing all resilient floor covering structures or contact your retailer or Armstrong World Industries Inc.

Place opened cartons of planks in the room where they are to be installed for at least 48 hours In drier climates below 25 RH or very humid climates above 60 RH allow 96 hours of acclimation time. Newly installed flooring should not be exposed to rolling load traffic for at least 72 hours after installation to allow the adhesive to dry. Armstrong S-288 or S-543- Non-Porous Substrates.

The floor is your canvas and your visual pallette are the colours of this stylish selection. Vinyl Sheet Floor Installation Vinyl Tile Installation Vinyl Sheet Floor Installation See also Floor Plans For Tiny Houses On Wheels. If rolling loads cannot be avoided protect the newly installed commercial flooring for 72 hours after installation by covering with wood panels.

Install pieces as recommended. Install the flooring according to the Armstrong Flooring installation instructions. Do not wet wash machine scrub or strip the floor for at least five days after installation.

The floor covering or adhesive in this package does NOT contain asbestos. Engineered Tile PDF 1585 KB RIGID CORE FLOORING INSTALLATION GUIDES AngleAngle Rigid Core PDF 4815 KB VINYL SHEET FLOORING INSTALLATION GUIDES Tough Guard II PDF 2424 KB Fiberglass-Reinforced Sheet Flooring PDF 1969 KB VINYL TILE FLOORING INSTALLATION GUIDES Vinyl Tile PDF 14 MB. The bottom end of the finish molding will rest on the top of the base molding with a straight cut.

Roller and other tools. Armstrong Commercial Flooring Installation Instructions. Installation of Commercial Resilient Flooring This course reviews proper subfloor preparation and components of a successful installation which include jobsite conditions product acclimation and tools for the job.

Overlap piece 2 onto piece 1 approximately 12 127 mm. The area to receive resilient flooring and the flooring materials and adhesives should be maintained at a minimum of 65 F 18 C for 48 hours before installation during installation and 48 hours after completion. INTRODUCTION Floating Floor Structure Armstrong Laminate Flooring is considered a floating floor and is installed using a.

Find the right installation tools for every commercial flooring project. Detailed instructions for those designs are available at. The final design and installation parameters are the responsibility of your design team.

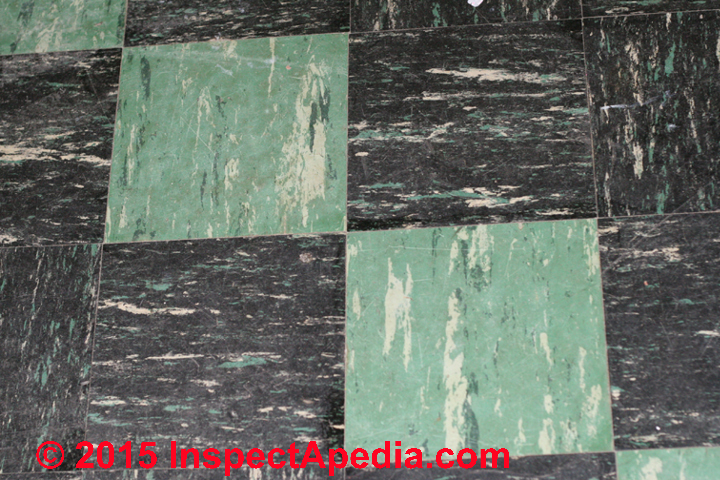

Armstrong Commercial Flooring Installation Instructions. The Armstrong collection of homogeneous and heterogeneous vinyl floor covering includes a wide selection of chip designs marbled and directional patterns a. Apply the S-288 or S-543 Adhesive over the area being careful not to cover the chalk lines.

Excess moisture can interfere with the adhesive andor seam treatments. You may prefer to install one quarter of the room at a time by starting in the center of the room Refer to Chapter 6 Layout and Fitting Section B for layout instructions. Visit the Technical and Downloads page for a full listing of product installation instructions.

You should hear an affirmative snap noise once the plank is in its proper position. We will also review ASTM F 710 guidelines and discuss installation methods for heat welding coving and wall base. Gather additional materials and tools.

Check your installation instructions for specifics. For panels weighing greater than or equal to 3 lbsSF use 12 gauge hanger wire 36 on center to support the main beams. For panels weighing less than 3 lbsSF use 12 gauge hanger wire 48 on center to support the main beams.

Be sure the floor youre laying over is dry clean and flat. The length of the panels must be installed perpendicular to the main beams see ceiling layout and section details. The recommended adhesives are S-288 S-289 and S-543.

Make sure the clip is fully entered into the grooves. Armstrong Ceilings has evaluated certain design configurations. Miter the top end of the finish molding so that the rabbet in the back of the molding is 18 higher than the panel if the panel does not go to the existing ceiling.

Your list could include adhesive double-faced flooring tape a vinyl cutting knife a 100 lb. Project specific evaluation for compliance with building codes is recommended. The first main beam should be no more than 12-12 off the wall and then 48 on center across the installation.

Hold the carrier down while pushing up on the plank.

Stainmaster Locking Luxury Vinyl Floor Installation Vinyl Flooring Interlocking Vinyl Flooring Vinyl Plank Flooring

Vinyl Sheet Flooring Armstrong Flooring Residential Vinyl Sheet Flooring Armstrong Flooring Flooring

Best Of Armstrong Flooring Beverly Wv Phone Number And Description Armstrong Flooring Outdoor Flooring Flooring

Armstrong Makes It Easy For You To Coordinate Your Color Options To Create Eye Catching Designs Flooring Office Armstrongfloors Dosemeler Hali Saha Halilar

Vinyl Plank Flooring Prep Installation Centsational Style Waterproof Vinyl Plank Flooring Installing Vinyl Plank Flooring Vinyl Plank Flooring

Flooring Installation Flooring Installation Association Of North America Flooring Instal Wood Floor Installation Laminate Flooring Laying Laminate Flooring

To Download Dlw Armstrong General Catalogue

Armstrong Commercial Striations Warm Gray Bio Based Tile 44 Sq Ft Carpet Colors Grey Carpet Vct Flooring

Carbide Charm Stratamax Value Plus Vinyl Sheet Flooring Vinyl Sheets Flooring

Armstrong Flooring Vinyl Tile 4 1mm Mineral Core Glue Down Alterna Collection Armstrong Vinyl Flooring Armstrong Flooring Vinyl Tile

收藏 Shinnoki Wood Texture Texture Veneers

Armstrong Timberbrushed White Oak Limed Beach Getaway 7 5 In Engineered Hardwood Oak Engineered Hardwood Armstrong Hardwood

Lino Pattern Vct Flooring Commercial Flooring Flooring

Masland Contract Product Details For Style Listen Shown In Color Reveal Tile Installation Home Decor Carpet

Maintenance Click Here For Maintenance Information Features Each Plank Is 4 5 In X 48 In Luxury Vinyl Tile Luxury Flooring Basement Flooring Waterproof

Pin By Carol Packard On For The Home Vct Tile Kitchen Flooring Flooring

Linoleum Floor Is A Type Of Eco Friendly Flooring Library Design Interior Using Linoleum With Yell Linoleum Flooring Eco Friendly Flooring Commercial Flooring